Dyeing Plant Wastewater Treatment Flocculant

2026-02-02

Sewage treatment chemicals for printing and dyeing factory, polyacrylamide

Case name: printing and dyeing plant sewage treatment

Pollution problem: high content of organic pollutants, alkalinity

Solution: the use of polyacrylamide treatment

Treatment effect: meet the discharge standards

Printing and dyeing plant sewage treatment process usually includes hydrolysis acidification treatment, activated sludge treatment, coagulation and sedimentation treatment, biological contact oxidation treatment, filter treatment and disinfection treatment of six steps.

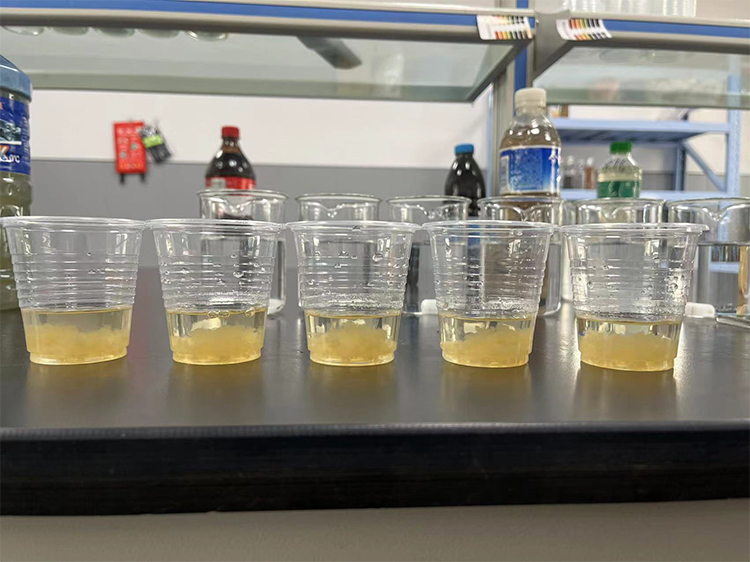

In each process step, there are different chemicals to be used. The use of polyacrylamide is mainly in the process of coagulation and precipitation, we will be treated by activated sludge wastewater into the coagulation tank, add anionic polyacrylamide, and then the cohesion of the material in the sedimentation tank for precipitation, to remove suspended solids, colloids and other substances in the water.

After precipitation of sludge after preliminary conditioning, through the filter press dewatering treatment can be, in the process of dewatering to be used in the printing and dyeing plant wastewater treatment with polypropylene cool amine as a sludge dewatering chemicals to use, generally this link is recommended to use the cationic polypropylene cool amine, which can effectively reduce the water content of the sludge, so that the sludge dewatering effect is good.

Henan Hangrui Environmental Protection Technology Co., Ltd. has rich experience in printing and dyeing industry sewage treatment, is a professional R & D and production of polyacrylamide company, can provide customers with effective solutions.

English

English